Mechanical Drives Learning System (46100)

The Mechanical drives learning system exposes students to the hardware, tools, measuring apparatus, and methods used by industrial mechanics to keep plants running. It covers the identification, installation, and troubleshooting of common machine elements, and is suitable for beginners in vocational schools, as well as industrial mechanics who need to refresh their basic skills. Hardware is of industrial-grade, yet small and light enough to be handled by one student. Most of the hands-on exercises take place inside an ergonomic and safe workstation which is the foundation of the system.

The Mechanical drives learning system is divided into a Workstation package (required for all topics) and four levels. Each level consists of separate models that include hardware, tools, measuring apparatus, and instructor manuals. Optional topics and hardware are also offered.

Mechanical Drive Training System, SI Units- Level 1 (Add-On)

Properly aligned pulleys, sprockets, and gears as well as adjustment of belt tension, chain slack and gear backlash are essential in mechanical drives. The Level 1 package includes hardware and tools to master these skills.

Future industrial mechanics must be trained to master the fundamental skills related to the identification, installation, and maintenance of belt, chain, and gear drives to minimize vibration, maximize power transmission, and help ensure that components reach their expected service-life.

The manuals of the Level 1 package guide the students step-by-step during their learning process with several photos and illustrations. The pulleys, sprockets and gears are stored on a panel for quick identification and inventory control.

Features & Benefits

- Identify and install belt, chain and gear drives

- Align pulleys, sprockets and gears

- Adjust belt tension and chain slack

- Adjust gears backlash

- Calculate speed and torque ratios

Mechanical Drive Training System, SI Units- Level 2 (Add-On)

Building on the knowledge gained in Level 1, Level 2 provides students with more learning opportunities in installation procedures of hardware commonly used in a variety of belt drives, chain drives, and gear drives.

There are several types of belts, pulleys, chains, sprockets, and gears suited for specific applications. Industrial maintenance students need to be able to identify and install them according to specifications. A selection of the most common ones is included in Level 2, along with new hardware and tools to teach these skills.

The manuals of the Level 2 package guide the students step-by-step during their learning process with several photos and illustrations. The pulleys, sprockets and gears are stored on a panel for quick identification and inventory control.

Topic Coverage:

- Identify and install wedge and notched wedge v-belts, synchronous and high-torque synchronous belts, and idler pulleys

- Identify and install variable-speed and multiple-speed belt drives as well as multiple-belt configurations

- Identify and install components of multiple-chain drives and the correct configurations of an idler sprocket

- Identify and install helical and miter gears

- Learn to disassemble a gearbox and identify its main parts

Mechanical Drive Training System, SI Units- Level 3 (Add-On)

This package covers two important aspects of mechanical drives. A variety of couplings are introduced while learning various shaft alignment methods. Installation methods for several types of bearings and seals are also detailed.

A fundamental aspect of mechanical drives is the axial transmission of torque from a driving machine to a driven machine. This is achieved by joining the shafts of each machine through a device called the coupling. A key requirement of any coupling is the alignment of the shafts.

Benefits:

- Align shafts using the straight-edge/feeler gauge, rim/face, and reverse dial indicator methods

- Use a laser alignment tool to align two shafts (optional hardware required)

- Identify and install various types of couplings

- Install/remove bearings and seals from shafts and housings using a variety of tools and methods

- Install/remove shaft lock nuts, lock washers, and snap rings

Mechanical Drive Training System, SI Units- Level 4 (Add-On)

This package introduces clutches for various operating conditions along with their proper installation procedures. And the topic ball screws and linear bearings introduces the main components and proper assembly steps of a linear slide.

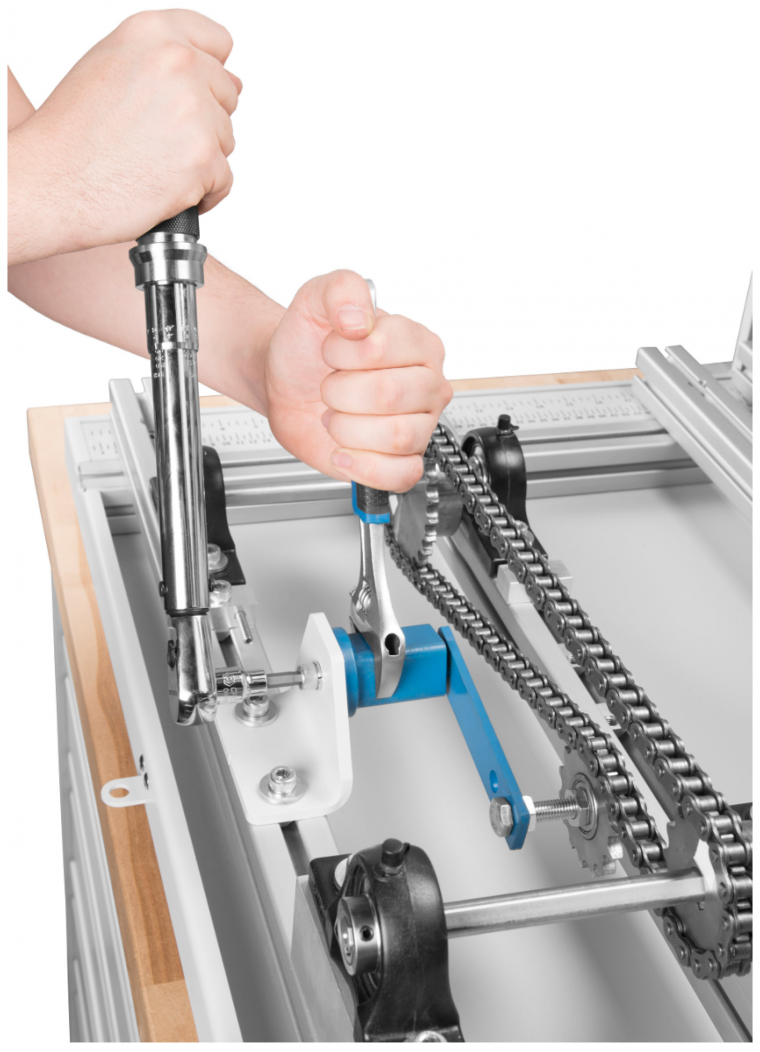

Several industrial applications, such as some conveyors, may require a load to be engaged/disengaged or braked while the motor keeps running. Other applications require the torque to be limited to protect mechanical equipment from overload caused by shock loads or machine jamming. The topic Clutches and brakes introduces those aspects and presents clutches for various operating conditions along with their proper installation procedures.

- Identify and install a freewheel clutch in a chain drive

- Identify, assemble and install a torque limiter in a chain drive

- Install an electromagnetic clutches/brake unit in a chain drive and test its different operating modes

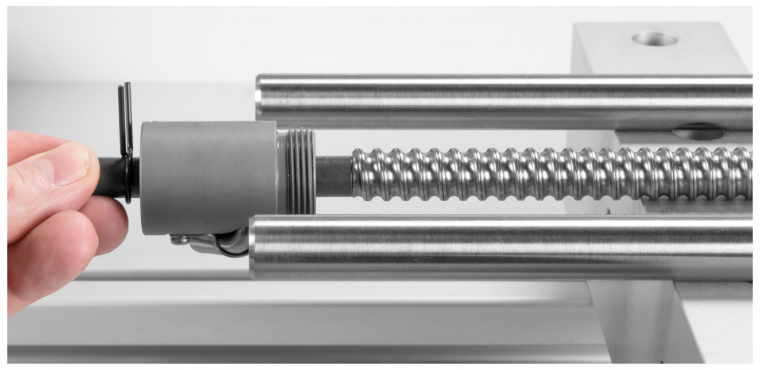

- Assemble a linear slide using ball nuts and ball screws

- Measure backlash and determine start, pitch and lead of a ball screw