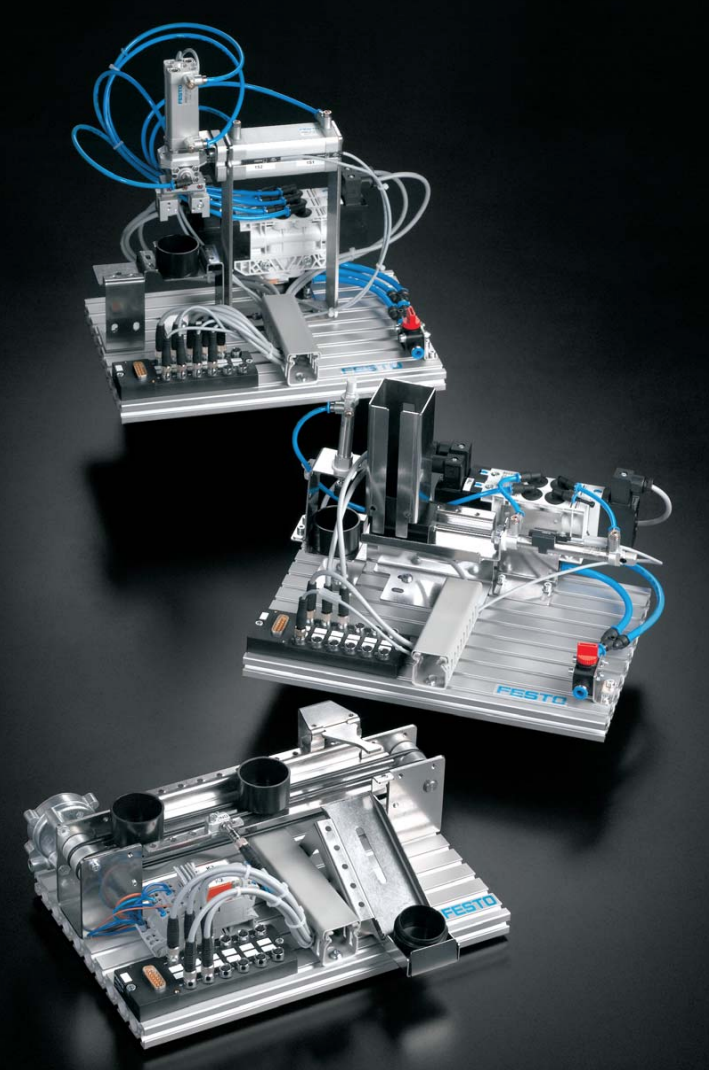

MecLab Training System

MecLab® is delivered in practical, stackable Systainers, which function as storage units and is delivered fully assembled and ready for immediate use. The three MecLab stations represent simplified models of typical production processes found in most automated factories. The individual stations have different functions: The Stacking Magazine station contains a workpiece storage container and a feed separator. The Conveyor station can transport and sort workpieces. The Handling station can grip the workpieces and deposit them at defined points. MecLab stations can be used individually. Each station performs a practical function and safely demonstrates the characteristics of a fully automated process. The stations can be joined together to form more complex “production lines”. Students can take on the role of engineer and design special exercises and projects, including joining the three stations together to form a mini production line.

Benefits

- Learning objectives – MecLab covers a variety of topics and objectives such as introduction to industrial automation technical terms, pneumatic and electrical actuators, sensors and controllers, open and closed-loop control systems and more!

- Variety of learning resources – The MecLab System comes with a variety of educational resources such as a supporting textbook, workbook with 5-7 exercises per station, powerpoint presentations with videos and more).

- Supports concepts in STEM – MecLab is designed to support concepts in Science, Technology, Engineering and Mathematics by encouraging students to experiment with computerized control of fluid power devices.

- Modular and flexible – MecLab stations can be used individually. Each station performs a practical function and safely demonstrates the characteristics of a fully automated process. Students join stations together to form more complex “production lines”.