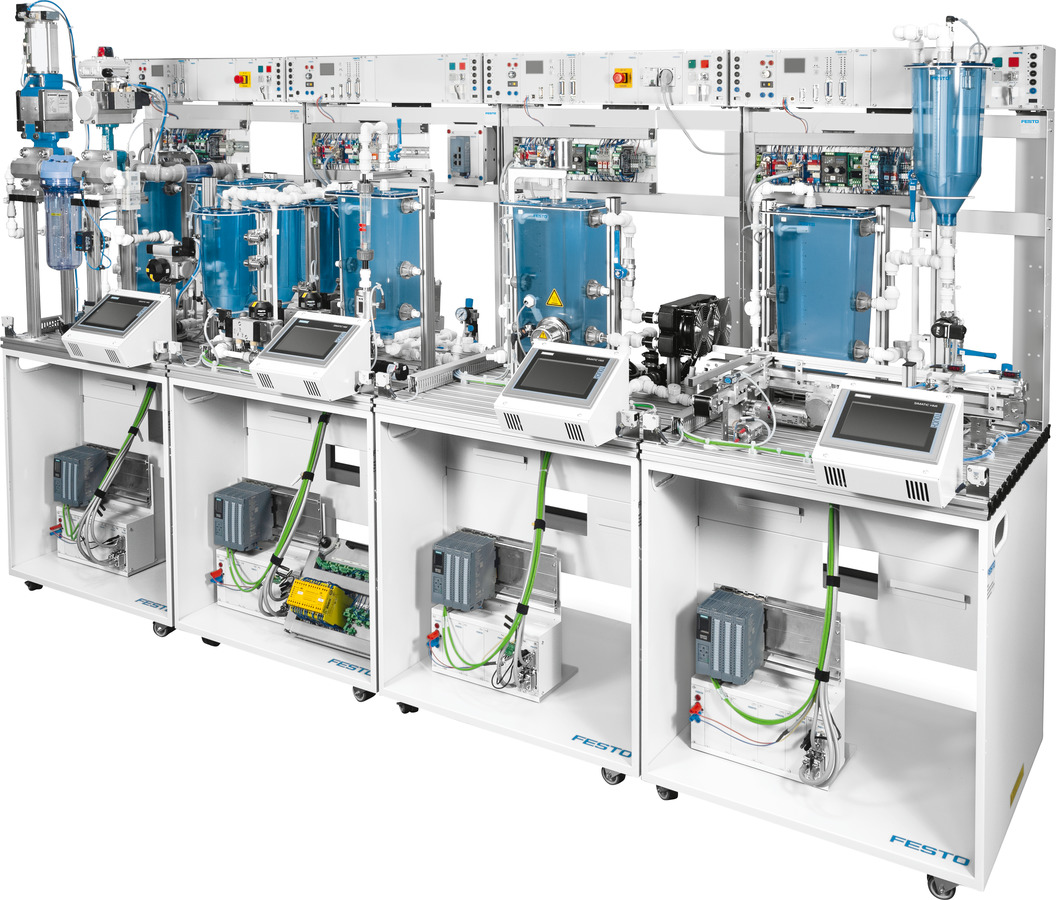

MPS PA 204 Complete System

The MPS PA complete process learning system teaches students about the fundamentals of filtration, mixing, reactor and bottling processes, just like in the industry. This system combines the Filtration, Mixing, Reactor and Bottling stations.

The Filtration station filters a fluid. The filtrate is pumped out of the first tank via different process valves through the filter into the second tank. The filtered fluid is added to the first tank in the Mixing station. The Mixing station mixes different recipes from three storage tanks. The finished mixture is pumped to the Reactor station. The Reactor station regulates the temperature of the fluid. Different temperature profiles, with different mixing times, are run depending on the selected recipe. The Bottling station bottles the fluid. The bottles are carried on conveyor belts to the bottling position and separated by a pneumatic separator. The bottles are filled with different quantities from the dosing tank, depending on the selected recipe.

Take a Glance at Each Individual MPS PA Learning System

The Bottling Learning System teaches students about the fundamentals of a bottling process typically found within industrial process automation. The bottling station fills bottles with liquid. The liquid is pumped into the dosing tank from the reservoir.

These bottles are transported to the filling position via conveyors. A pneumatic separator then separates the bottles where they can be filled properly according to the selected recipe.

Used as a stand-alone station or in combination with other stations, this learning system teaches the fundamentals of a filtration process. The filtration station filters liquids. The filtrate is pumped from the first tank into the second tank through the filter using a knife gate valve. The filtered liquid reaches the second tank via the flap with pneumatic semi-rotary drive. It can be pumped to the next station using a separate pump. The filter can be rinsed using a rinse program. Regulated compressed air is additionally blown through the filter to loosen deposits.

Used as a stand-alone station or in combination with other stations, this learning system teaches the fundamentals of a mixing process. The mixing station mixes different recipes from three reservoir tanks. The liquid from one of the three reservoir tanks is pumped into the main tank in a controlled manner by opening the respective two-way ball valve. The finished mixture can be pumped to the next station via a second pump or pumped back to the reservoir tank. Using a constant flow rate, the three raw materials are mixed to a recipe in the mixing station.

The reactor station teaches the basics of process control, which is widespread in many industries. The reactor station brings the liquid to the right temperature. Depending on the recipe selected, different temperature profiles with different stirring times are activated. A cooling pump is activated to cool the liquid. The tempered liquid can be pumped on to the next station using a separate pump. Sensors record the fill level of the container in the reactor station. This makes it possible to teach everything from simple control tasks for monitoring the pumps to