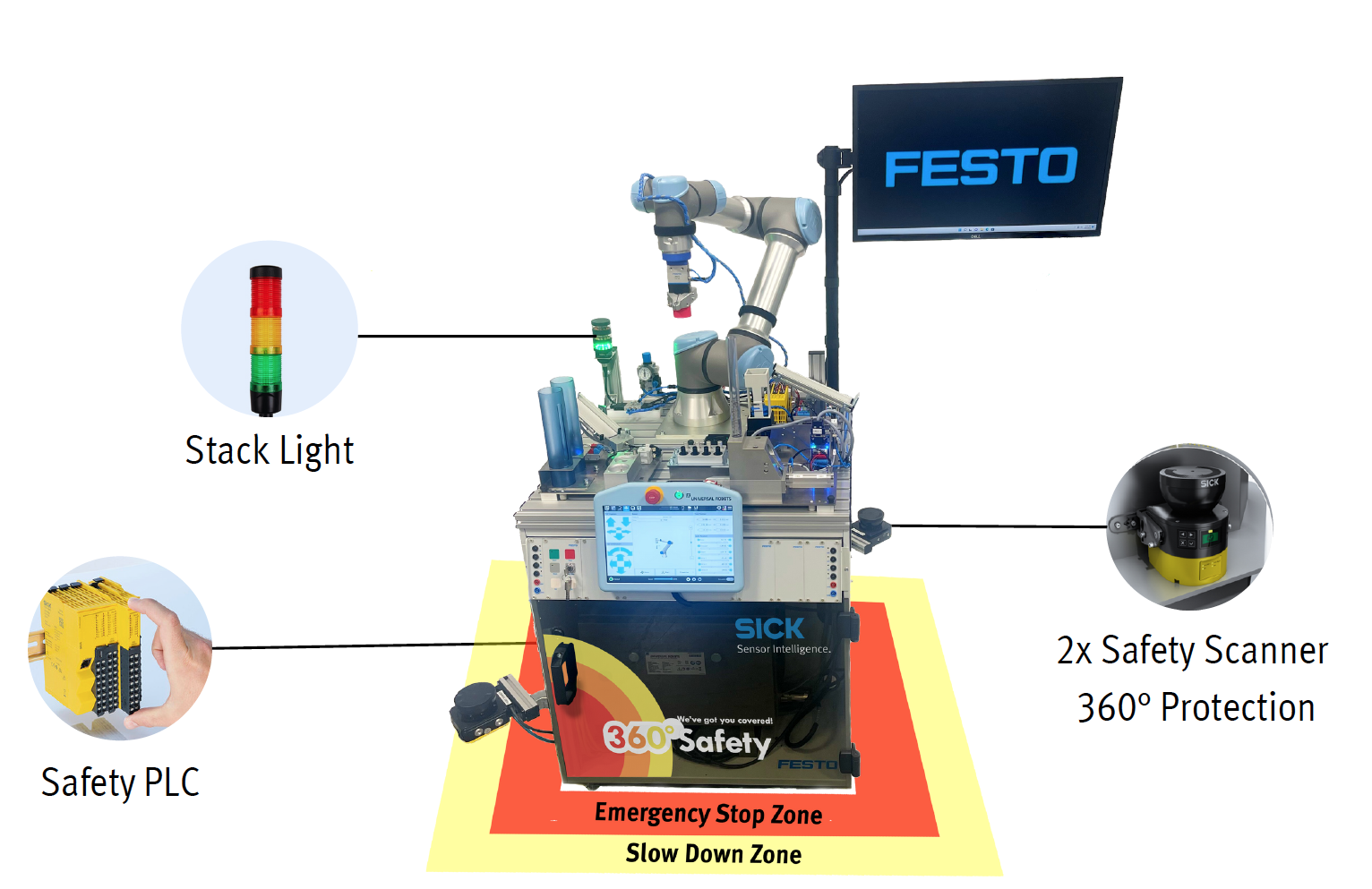

SICK Sensor Safety Awareness Package

The SICK Safety Awareness Package focuses on robot risk assessments and the implementation of the system approach. The hardware consists of a Festo Didactic manufacturing production system (MPS), a simulated Cyber-Physical Smart Factory with six-axis robot, SICK area scanners, safety PLC and safety relay.

Through this developed curriculum, students are walked through the Six Step Method to Risk Assessment for Robotics and Automation equipment safety. The six steps consist of: risk assessment, safe design, technical protection measures, administrative measures, overall machine validation and deployment of machinery. Students also learn the definition of key terminology, such as performance measures, areas of severity, frequency, and avoidance.

What’s in the Package?

- Stack Light

- Safety PLC

- Estop

- 2x Safety Scanner 360 Degree Protection

- Curriculum with Risk Assessment Worksheets

Compatible with Universal Robots, along with other leading Robotic Manufacturers

Benefits

- Rapid deployment – With the Quick Start Guide, one can achieve rapid deployment upon delivery of the

system - Curriculum – The SICK Safety Awareness Package comes with comprehensive curriculum for student learning including instructor notes and guides

- Certifications – Offered certification by Festo and NC3

- Compatibility – Compatible with standard mechatronics MPS systems as well and Industry 4.0 versions