Vectis Standard Air-Cooled Cart-Based System

The Vectis Cobot Welding Tool helps manufacturers boost productivity amid the shortage of skilled labor by reducing the learning curve, setup time, risk, and cost of robotic welding. Powered by a Universal Robots UR5e or UR10e collaborative robot, the Vectis Cobot Welding Tool is portable, safe, versatile, and extremely easy-to-use. The system is fully integrated onto a 3ft x 6ft mobile modular fixturing cart so you can bring the cobot to the work, or the work to the cobot. Most users are setup and welding within a few hours of arrival – with no programming experience necessary. Through the use of the Vectis Cobot Welding Tool, production of automating simple and repetitive parts has never been easier. The Cobot Welding Tool can be entrusted to handle smaller, more simple tasks, allowing for the cobots human counterparts to be able to spend more time on more complex tasks.

The “Ready to Weld” Integrated Application Includes:

- Cobot (UR5e or UR10e)

- Miller Invision 352 MPa welder

- Miller wirefeeder adapted for cobot use

- Air-cooled welding torch

- Mobile cart with 30″ x 48″ fixturing surface and 66pcs of starter fixturing

- Operator panel

- Vectis’ proprietary Let’s Weld Together™ software to make programming quick and easy

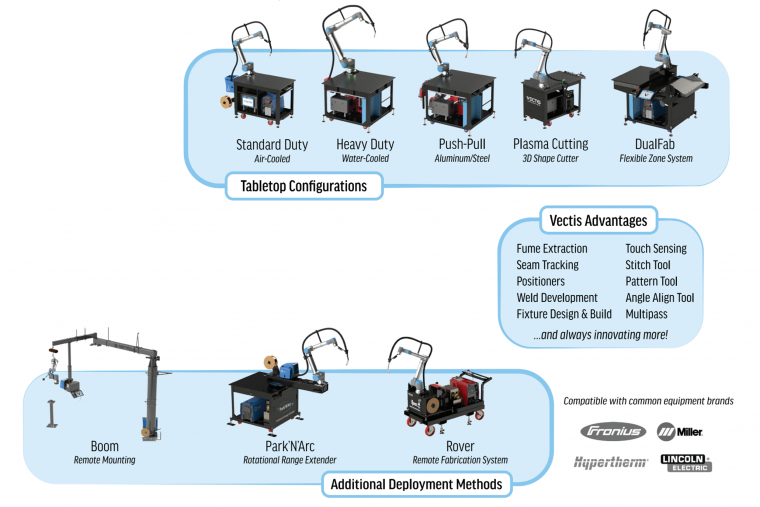

Other Tabletop Configurations and Deployment Methods

Benefits

- Easy-to-Use – No programming experience needed. Make your first weld/cut within 10 minutes of plug-in using Vectis’ intuitive interface, weld templates, and tutorials.

- Cobot Powered – Freedrive jog enable button that allows the programmer to teach the cobot by physically moving the cobot to program points.

- Produce Faster – Vectis’ solution ships in a few weeks, DIY setup in 2 hours after arrival. Most customers see a 2-4x productivity boost.

- Lower Costs – All-in price. No hidden costs and no subscription fees (20-45% less than traditional cells).